GLYPHOSATE ANALYSIS IN FOODS

BY HPLC WITH POST-COLUMN DERIVATIZATION AND FLUORESCENCE DETECTION

Glyphosate, the active ingredient in Roundup®, is the most widely used herbicide in the world. In the United States, the Environmental Protection Agency (EPA) regulates Glyphosate and sets maximum amount of herbicide allowed to be present in assorted crops as well as drinking water. Recent research, however, has raised concerns about Glyphosate safety and its prevalence in the environment. In response to the evidence of increased human exposure to this herbicide, the Food and Drug Administration (FDA) announced it will begin testing Glyphosate in foods including soybeans, corn, milk, and eggs.

Pickering Laboratories has over 30 years of experience manufacturing and selling instruments and reagents for Glyphosate analysis in accordance to the US-EPA Method 547 for Glyphosate Analysis in Drinking Water as well as the AOAC Method 991.08 for Glyphosate Analysis in Environmental Waters. These HPLC methods are based on post-column derivatization technology with florescence detection. The AOAC Official Method 2000.05 for Analysis of Glyphosate in Crops describes an easy clean-up procedure using cation-exchange cartridges that was successfully combined with Pickering Laboratories’ post-column derivatization for analysis of Glyphosate in crops such as soy, corn, alfalfa, and sunflower seeds as well as vegetables such as tomatoes and broccoli (1, 2). The downside of this sample preparation technique is the fairly high volume of the water-based solution used to elute Glyphosate from the clean-up cartridge and consequently long evaporation times.

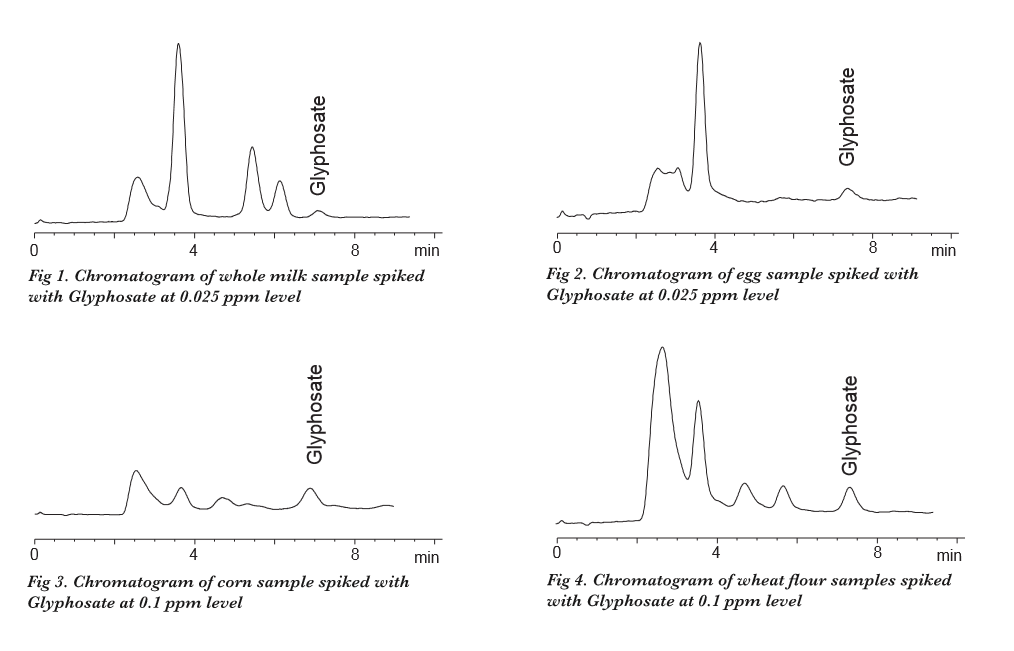

The presented post-column derivatization method for Glyphosate analysis utilizes an accelerated sample preparation procedure to quickly and efficiently analyze Glyphosate in a wide range of foods. The analytical method is sensitive and selective, and it can be easily implemented in any laboratory.

METHOD

Analytical Conditions

Column: Cation-exchange column, K+ form, P/N 1954150

Guard Column: Cation-exchange GARDTM Column

Protection System P/N 1700-3102

Column Temperature: 55 ºC

Flow Rate: 0.4 mL/min

Mobile Phase: K200, RG019

Injection Volume: 100 uL

HPLC GRADIENT

|

TIME (Min) |

K200, % |

RG019, % |

|---|---|---|

|

0 |

100 |

0 |

|

15 |

100 | 0 |

|

15.1 |

0 | 100 |

|

17 |

0 | 100 |

|

17.1 |

100 | 0 |

|

25 |

100 | 0 |

Post-column Conditions

Post-column System: Pinnacle PCX or Vector PCX

Heated Reactor Volume: 0.5 mL

Temperature: 36 ºC Ambient Reactor: 0.1 mL

Reagent 1: 100 uL of 5% NaOCl (Bleach) in 950 mL of GA116 Diluent

Reagent 2: 100 mg of OPA and 2 g of Thiofluor in 950 mL of GA104

Diluent Reagent Flow Rate: 0.3 mL/min each reagent

Detection: λex = 330 nm, λem = 465 nm

Supplies for Sample Preparation

Methylene Chloride, HPLC Grade

Methanol, HPLC Grade

Elution Solution (90% Methanol – 10% 1N HCl)

RESTORETM solution (P/N 1700-0140)

SAX cartridges, 500 mg, 6 mL (Agilent Bond Elut, P/N 12102144)

Sample Preparation

Extraction

To 25 g of homogenized sample, add enough water (after estimating moisture content) such that the total volume of water is 125 mL. Blend at high speed for 3-5 min and centrifuge for 10 min. Transfer 20 mL of the aqueous extract into a centrifuge tube and add 15 mL of Methylene Chloride. Shake for 2-3 min and centrifuge for 10 min. Use the upper layer for SPE clean-up. Matrix-Specific Modifications 1) For samples that absorb large amounts of water, reduce test portion to 12.5 g while keeping water volume the same. 2) For samples with high fat content, do the Methylene Chloride partitioning twice. SPE Cleanup Condition the SAX cartridge with 5 mL of Methanol followed by 5 mL of D.I. water draining the liquid to the top of the sorbent bed. Transfer 1 mL of extract and elute to the top of the sorbent bed. Wash with 5 mL of Methanol. Elute Glyphosate with 5 mL of Elution Solution. Evaporate to dryness at 55 ºC. Dissolve the residue in 1.5 mL of a solution of 10% RESTORETM in water, filter through a 0.45 um syringe filter and inject onto the HPLC column.

RECOVERIES FOR GLYPHOSATE

| MATRIX | EPA TOLERANCES | SPIKE LEVEL 1 | RECOVERIES | RSDr, | SPIKE LEVEL 2 | RECOVERIES | RSDr, N=3 |

|---|---|---|---|---|---|---|---|

| Rolled Oats | 20 ug/g | 0.1 ug/g | 85% | 1.6% | 0.2 ug/g | 87% | 4.9% |

| Wheat Flour | NA | 0.1 ug/g | 88% | 4.6% | 0.2 ug/g | 87% | 1.3% |

| Whole Milk | NA | 0.025 ug/g | 99% | 3.9% | 0.05 ug/g | 92% | 2.9% |

| Eggs | 0.05 ug/g | 0.025 ug/g | 75% | 2.8% | 0.05 ug/g | 77% | 5.1% |

| Soybeans | 20 ug/g | 0.1 ug/g | 77% | 6.7% | 0.2 ug/g | 74% | 5.5% |

| Corn | 5 ug/g | 0.1 ug/g | 94% | 3.7% | 0.2 ug/g | 99% | 3.6% |

| Beer | NA | 0.025 ug/g | 78% | 6.9% | 0.05 ug/g | 73% | 3.6% |

Conclusion

The simple and robust post-column method was shown to be suitable for analysis of Glyphosate on sub-ppm levels in many types of foods. Accelerated sample preparation improves throughput of samples and reduces cost of testing for busy laboratories. The sensitivity of the method allows for detection of Glyphosate well below residue tolerances set by regulatory agencies.

REFERENCES

1. Pickering Laboratories method abstract MA207 “Glyphosate Analysis in soy beans, corn and sunflower seeds”

2. Pickering Laboratories method abstract MA206 “Glyphosate and AMPA Analysis in crops”