New Product Lines from Pickering

Mycotoxin product line (PDF)

Mycotoxin product line (PDF)

We are now distributing Mycotoxin Immunoaffinity products for Ochratoxin and Aflatoxin. The performance and batch-to-batch reproducibility of the columns is exceptional and far exceeds that of other manufacturers. The columns can be used for any matrix, from wine and juice, to nuts and grains, to herbs and spices. Contact Sales for more information.

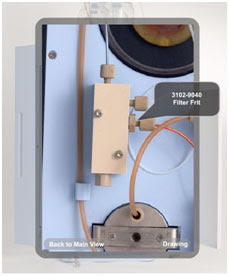

GPC Sample Clean Up Line Products Page

We have a new GPC Sample Clean-up product line! We have both automated and manual GPC cleanup systems and we also have systems that include concentration & solvent exchange, or just GPC. Sample cleanup using GPC is especially useful for fatty matrices, but also perfect for vegetable matter and spices, as well as soil & waste water.

New faster AAA columns Products Page

We now have a Lithium amino acid run which will separate 45 amino acids in 70 minutes for Physiologic fluids, an a new 30-min Sodium amino acid run which will separate the 20 amino acids commonly found in protein hydrolysate samples. These columns are for use with our Pinnacle PCX.

Our newly launched Histamine product line consists of Dip-sticks and Elisa kits as well as Post-column derivatization for fast and in-situ testing as well as quick, reproducible, and sensitive methods for follow-up confirmation. Contact Pickering Laboratories at 1-800-654-3330 or sales@pickeringlabs.com for more information!