Chromatography Quiz #35 – Bad Carbamate Chromatography

Pickering Labs would like to congratulate all of our winners for our previous newsletter’s Chromatography Quiz:

Mark Ritari from Anatek Labs Inc., Jim Balk from Nebraska Public Health Environmental Lab, Josiah Hakala from Minnesota Department of Health, and Narjes Ghafoori from Los Angeles County Public Health Laboratory.

Winners will soon receive: Amazon eGift Card! ($100 value)

Congratulations to our quiz winners!

Thank you all for your submissions!

In this case, the cause for the bad chromatography was a damaged or old heated reactor coil. However, poor peak shape can be caused by many possible issues. Here is a beautifully summarized answer to the quiz from one of our winners:

Observation: Peak Tailing observed for all target compounds- more extensive for earlier eluting chromatography peaks, carbaryl and 1-naphthol not as affected. Extensive tailing will cause integration problems for choosing area or peak height as a response variable. Peak retention and selectivity not affected, compromise in resolution but peak separation is still present. There are multiple causes of peak tailing. Unwanted secondary interaction between the analyte and stationary phase can lead to peak shape problems leading to peak tailing and loss of efficiency (sensitivity). Loss of resolution and difficulty with integration. One must have the proper instrument setup (detector time constant) and proper connections to eliminate extra column dead volume (connecting tubing, inline frits, guard column) to maintain column efficiency. The presence of trace metals can cause increases stationary phase silanol activity, leading to peak tailing from secondary interaction – use type B silica columns.

Possible problems could be coating or obstruction on column frit of particles coating the column from sample matrix and is very common. This will affect all peaks and is causes a increase in backpressure. This can be prevented by filtering sample prior to HPLC. Flushing with various solvents can help. If reverse flushing the column, replacing the guard column, and/or pre-column inline frit does not help, the column has been probably chemically damaged and should be replaced. Physical damage accompanied by pressure change, pressure shock, void present (bed deformation) in column bed will affect all peaks – the column will have to be replaced. I have injected 3-5 100uL 3% ChlorAC buffer in 30% methanol and running a gradient to 30% methanol (holding at 30% methanol for 30 minutes) and then 100% methanol for 1 hr at 1cc /min. It is important to that a proper guard column and sample solvent be used for the best peak shape. The sample must be properly buffered for carbamate analysis and the guard column be the sample packing material as the analytical column.

Diagnosis /Prognosis

- Analytical column problems (peak shape/loss of efficiency) has multiple causes; problems can be related to all components in the HPLC system (pump, injector, column, detector, data system/integrator).

- Use column protection (In-line filters /Guard columns); filter samples, mobile phase compatible sample solvent with properly sample-clean-up.

- Peak tailing, broadening, and loss of efficiency may be cause by column secondary interaction-metal cation activated or free silanol residues, column contamination, column aging, column sample mass/ volume overload, and/or extra-column effects (extra-column dispersion)

- In this case peak retention/selectivity has been affected. Some compromise in resolution has occurred because of peak tailing.

- Method development is important. Is the analytical column really the problem? Troubleshooting HPLC system components is necessary. Replacing the column with a new column (high purity Type B silica) may eliminate HPLC system problem as the cause of bad chromatography.

- Peak tailing for all peaks may be a physical rather than a chemical problem. The initial problem occurred before analytes began migrating through the column. This type of peak shape problem occurs with a partially blocked or void at the head of the column. Replacing or installing in-line frit (0.5 um porosity) downstream from the autosampler is an easy and less expensive to solve this type of peak distortion problem.

- For the diagnosis of the “bad chromatogram”, the abnormal peak shape (peak broadening/tailing) is particularly evident for all peaks with less noticeable distortion for carbaryl /1-naphthol. If all peaks in the chromatogram are affected, the problem may be related to either the column or the system. If only early eluting peaks are affected, then the problem lies within the fluid path (perhaps incorrect internal diameter of tubing, fittings, etc.). Problems with single peaks may suggest a specific chemistry problem in my experience. One also consider post-column broadening effects where extra-column band broadening or changes in the system are the most likely causes

Chromatography Quiz #36 – Amino Acids Bent Outa Shape

Correctly answer the question below and win a prize! Simply email your answer and your full contact information to Rebecca at rlsmith@pickeringlabs.com by November 15, 2020 in order to win. You will receive email confirmation when your submission is received, and the troubleshooting answer and winner congratulations will be published in the next issue (to be anonymous, please notify Rebecca in submission).

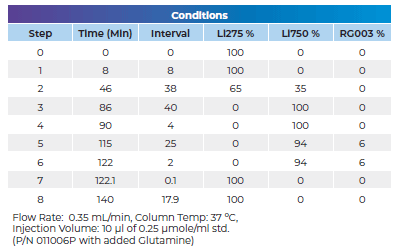

Below you will find the method details for the Amino Acids method. What could be causing the poor peak shape?

Analytical column: 0354100T–

Post-column Conditions

Post-column System: Onyx PCX, Pinnacle PCX, or Vector PCX

Reactor 1: 1030 ºC, 0.5 mL

Reagent 1: Trione

Detection: 570nm

Injection Volume: 10ul

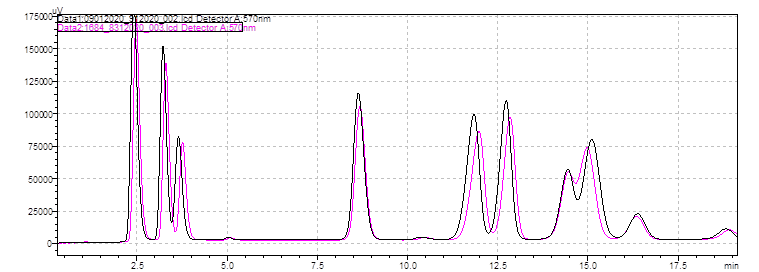

Black is a good chromatogram. Pink is the bad chromatogram.

Reference Chromatrogram:

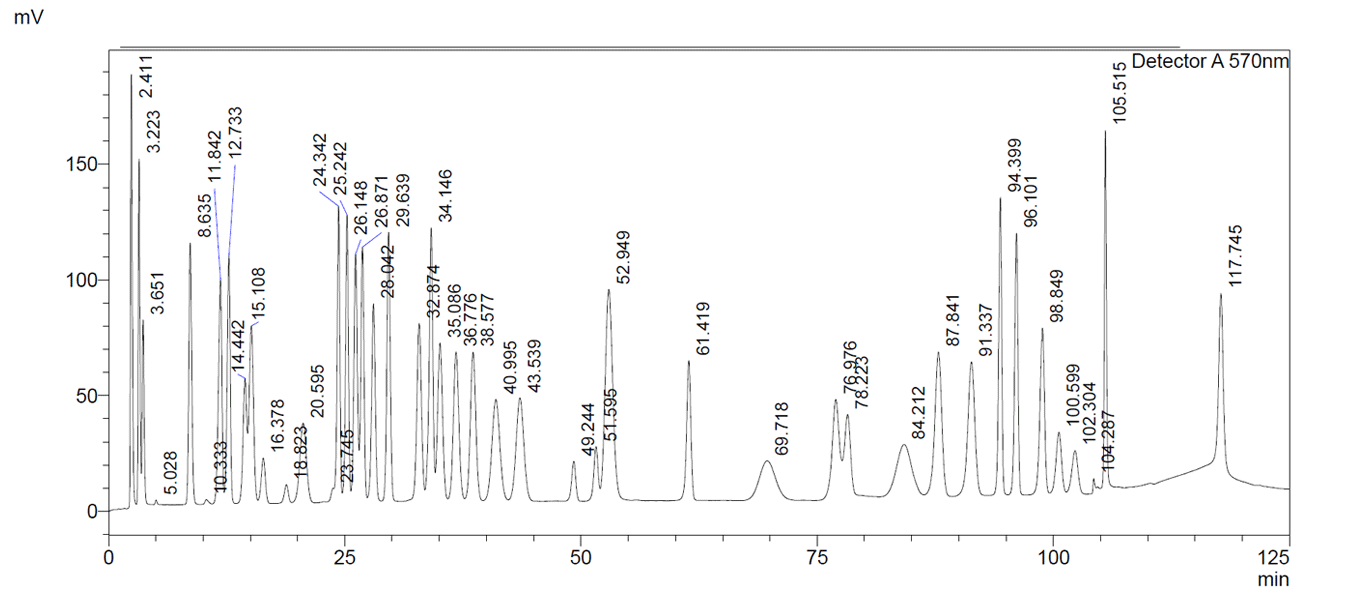

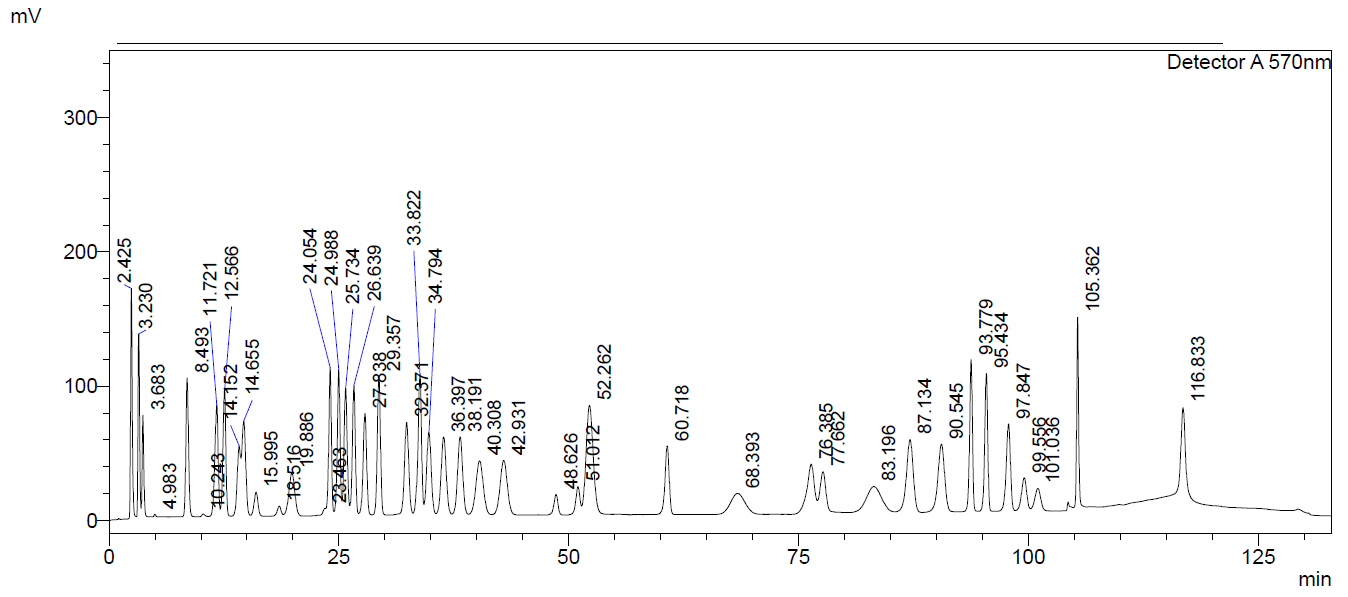

Bad Chromatogram: