By Saji George

There is a saying, “one cannot make an omelet without breaking a few eggs”. What do omelets and eggs have to do with post-column instrumentation? No direct correlation, but both have an underlying parameter that is important in achieving the final goal. Too much pressure on the egg and you will end up with egg shells in your omelet, too little pressure and there might not be an omelet.

There is a saying, “one cannot make an omelet without breaking a few eggs”. What do omelets and eggs have to do with post-column instrumentation? No direct correlation, but both have an underlying parameter that is important in achieving the final goal. Too much pressure on the egg and you will end up with egg shells in your omelet, too little pressure and there might not be an omelet.

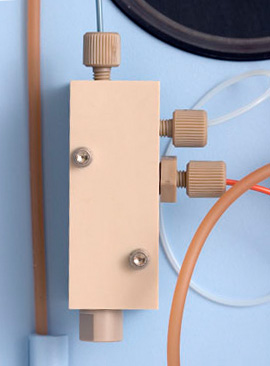

In the case of the post-column derivatizer, there is a sweet spot (pressure range) that relates to a system that is working well. The system pressure is mostly comprised of the reagent pump(s) pressure(s) and gives an idea of how the overall system is performing. Too high and there is a constriction problem, too low and there is a leak in the flow path.

The pump pressure measures the pressure downstream from the pressure transducer. This includes the heated reactor, filters, unions, detector, and flow path tubing. All of these components have to be looked into when troubleshooting a high pressure problem. The best troubleshooting method is to remove one component at a time to look for the pressure drop; it is best to work backwards (start from the outlet of the detector). Components to pay attention to are: back pressure regulator, detector, ambient reactor, heated reactor, restrictors if there are any and last but not least the reagent filters. A significant drop (greater than 100 psi) in pressure when one of the components is removed would indicate that it is the source of the problem. The same thought process works for leaks also! Take a lint free towel and wipe all connections one by one, looking for areas of wetness that would indicate a leak.

Since summer is around the corner and graduations, admissions applications and final exams (to name a few) have been taken care of, please do take time to hit the sweet spot by enjoying the great outdoors!